- Tempered Glass

- Laminated Glass

- Double Glazing

- Bended Glass

- Glass Services

- Benefit of Glass

- Shop Fronts & Office Partitions

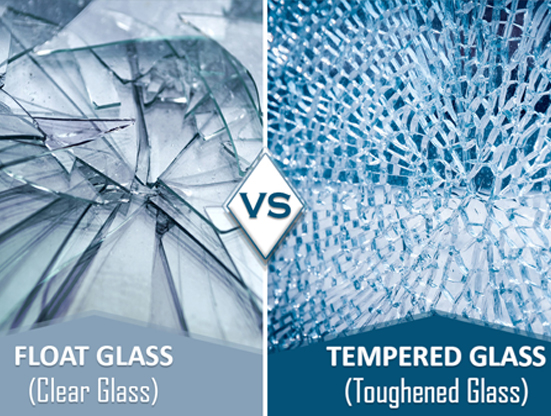

Tempered Glass

Tempered glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. Tempering puts the outer surfaces into compression and the interior into tension. Such stresses cause the glass, when broken, to shatter into small granular chunks instead of splintering into jagged shards as ordinary annealed glass does. The granular chunks are less likely to cause injury.

Process of Tempering Glass:

The following are the process of Glass tempering:

Tempering Glass Uses:

Tempered glass is used when strength, thermal resistance, and safety are important considerations. Since they are stored outdoors, they are subject to constant heating and cooling as well as dramatic temperature changes throughout the year.

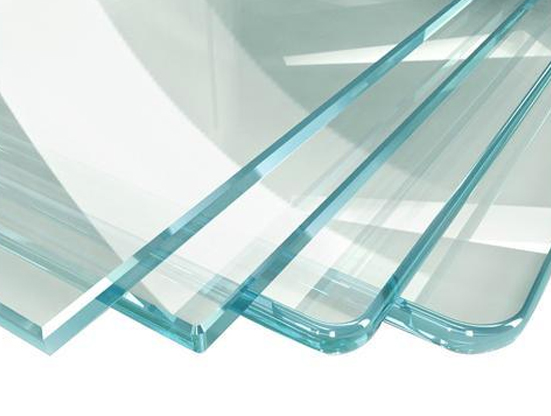

Temper Glass Thickness

The following are the thickness of glass we tempered

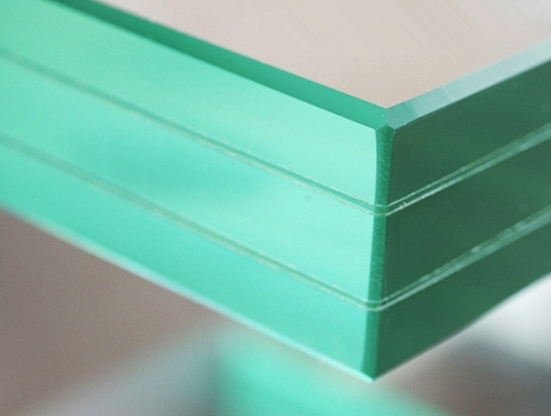

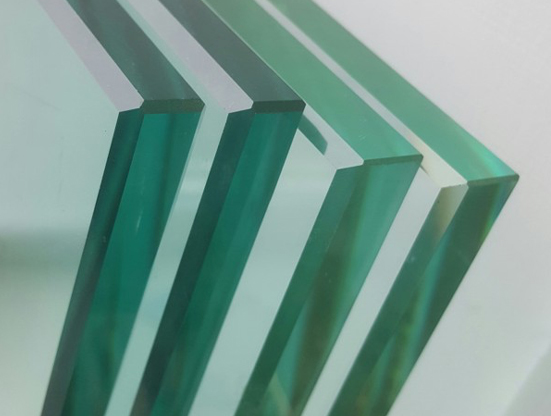

Laminated Glass

Laminated glass is a type of Safety Glass and is made by pasting PVB (polyvinyl butyral) resin glue film between two or more pieces of glass sheet, then heating, pressing and bonding them together to create flat or curved compound glass product.

Laminated glass is extra strong and extremely secure. It can provide UV protection against the harmful ultraviolet rays that fade furnishings. ItŌĆÖs hard to break. When broken, it will shatter but still hold its form, minimizing the risk of injury. It is durable and versatile. The thickness of the combined glass and the space between each pane can act as insulation and provide sound reduction.

Process of Laminated Glass:

The laminating process is carried out in the dust free laminating room. The staff is required to replace the cleaning sneakers before entering the laminating room, wear the cleaning work hood and gloves, and record the temperature of the laminating room. Humidity and moisture content of the film

Laminated Glass Uses

Laminated glass provides a very strong, yet transparent layer which makes a great alternative for traditional glass in a variety of uses:

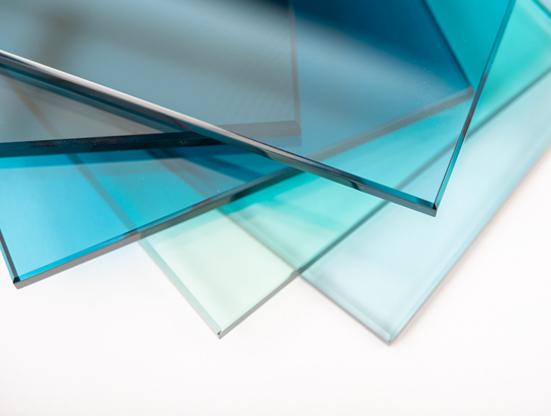

Thickness of PVB

Type of PVB

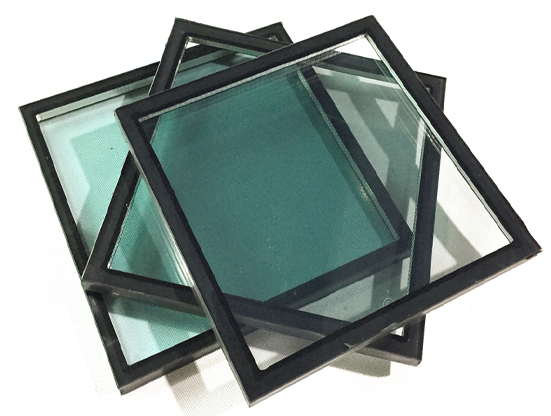

Double Glazing

A combination of two or more sheets of glass, separated by a spacer bar and sealed so that it forms a single unit, having one or more air spaces in between is called a Double-Glazed Unit. It is commonly referred to as 'double glazing glass' or 'double pane'. Double glazing or insulated glass evolved from the traditional double-hung windows and storm windows, which separated the interior and exterior spaces using a single pane of glass. The primary benefit of double glazing is thermal insulation ŌĆō to retain heat in a room whilst stopping cold air entering from outside to make the room more energy-efficient.

Process of Double Glazing:

The Double Glazing is step by step process:

Double Glazing Uses:

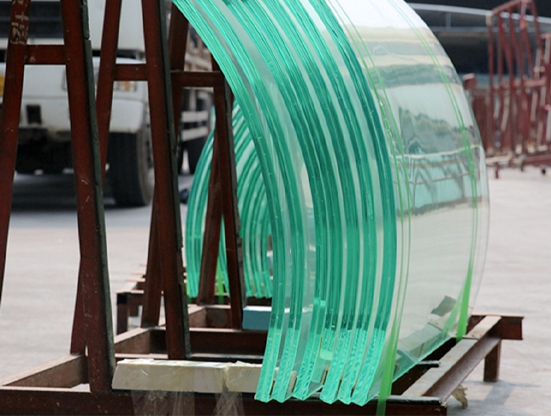

Bended Glass

Bending glass┬Āinvolves heating up to 600 degrees Celsius. The high temperature is sufficient to soften the glass to a condition where you can bend it. Using gravity or mechanical pressure we can pull the glass into the desired shape. Curved glass can be turned into a safety glass.

Bending Glass Processing:

Bended Glass Uses:

Glass Services

Glass Edge Polishing

This method involves cutting the edges of the glass and then flat polishing them, resulting in a sleek appearance and shiny or glossy finish. Most flat-polished applications also employ a small 45┬░┬Āangle chamfer on the top and bottom glass edges to remove sharpness and ŌĆ£chatterŌĆØ which can also be polished

Polished edges are┬Āproduced by buffing the edge of the glass with a fine abrasive material and polishing oil. The result is a beautifully translucent finish. Flat polished edges are excellent options for the thicker glass used in shelves and frameless shower enclosures.

Benefit of Glass

Because of its wide variety, glass can be used in a variety of applications, so it has a bright future and has always been loved by consumers. When we choose glass, in addition to paying attention to its price, we should also pay attention to the different properties of various types of glass, and choose the type that is more suitable for home use.

People are now concerned more about the impact of products used in construction. Glass is completely recyclable and it is the most environment friendly material used in construction. Further, the cost of installing bent glass has greatly reduced. All these properties related to glass have led to the rising importance of glass in architecture. With the use of glass, natural light can be let inside the building and people in the building can also get connected with the outer landscape. A sense of space can be established strongly with the use of glass in structures.

Just like light is transferred, glass has the tendency to let heat in. However, modern day technology uses different types of coating to insulate glasses used in buildings. This way, suitable amount of warmth is locked inside the building and it remains unaffected by the variation in temperature outside. The thermal insulation of bent glass is usually represented as K value.

To enhance the corporate image and to make the building stand out of the rest, curved surfaces are used in modern buildings. Facades have become essential in corporate buildings and using bent glass, different types of facades can be built. For aesthetic reasons too, glass is widely used in commercial and residential buildings

We Build Up With Your Dreams

We are Specialized in Architectural Designs, Glass Partitions, Shower Enclosure, Aluminum Doors and Windows, Glass Houses, Skylight Works & Designed Mirrors and Glasses

Office Partitions

We also do wide range of glass partition in Dubai of custom-made profiles as per client request like soundproof glass partition / acoustic glazing, framed partition. Jumbo size , crystal clear glass shop fronts with different designs.

We are specialists in the supply and installation of all types of office and glass partition systems ranging from all solid and part glazed partitions to full height single & double glazed glass walls in Dubai.

We are a professional Glass office partitions supplier in Dubai. We ideally use 10 mm glass and is frequently used for glass office renovation in Dubai. The reason for using the 10 mm thick glass is because it is less dense than the 12 mm thick glass. We also do office relocation within UAE; then we can help you with the cheap and best glass partition solution.

With our glass partition Dubai installation, you can meet the needs of a wide range of corporate clients without sacrificing your business goals. Commercial building owners who do not want to see their property vacant for prolonged periods will definitely benefit from our proven designs equipped with modular glass partition Dubai, which is also a highly cost-effective solution. Our glass wall systems come with a significant advantage over drywall and traditional sealed glass partitions.